Product Details:

Payment & Shipping Terms:

|

| Color: | Yellow,white | Specification: | 10t-165t Printing Mesh |

|---|---|---|---|

| Material: | 100% Polyester | Width: | 1-3.65m |

| Weave: | Plain Weave | Certificate: | ROHS, SGS, FDA |

| Pening (um): | 24-740um Printing Mesh | Standard Length: | 30m-70m/roll Printing Mesh |

| Samples: | 1m For Free |

Printing Material, Printing Mesh, Screen Printing, Polyester Mesh, Strong Weathering Resistance:

Comparison of wire mesh weaving methods (plain and twill):

Of course, all screens can be plain weave, and the woven screen has two decisive factors, namely the filament D and the mesh width W, which determine its plain weave or twill weave.

As the normal use, there are three forms of filament and mesh width: D < W, D = W, D > W. Generally, fibers having a filament D smaller than the width W are woven with plain weave.

The unfavorable side of plain weave is that weaving is difficult. For example, the 355T twill weave has 63,012 waveforms in2. Now, if weaving with plain weave, it will have 126,025 waveforms in2, which will cause a lot of pressure during weaving. Increasing the wave angle of the fiber sometimes causes inconsistencies, and the warp threads are excessively stretched when the mesh is stretched.

However, the printer can now buy both 355T and 390T plain and twill screens, but the plain weave screen tension is slightly lower than the twill weave screen tension.

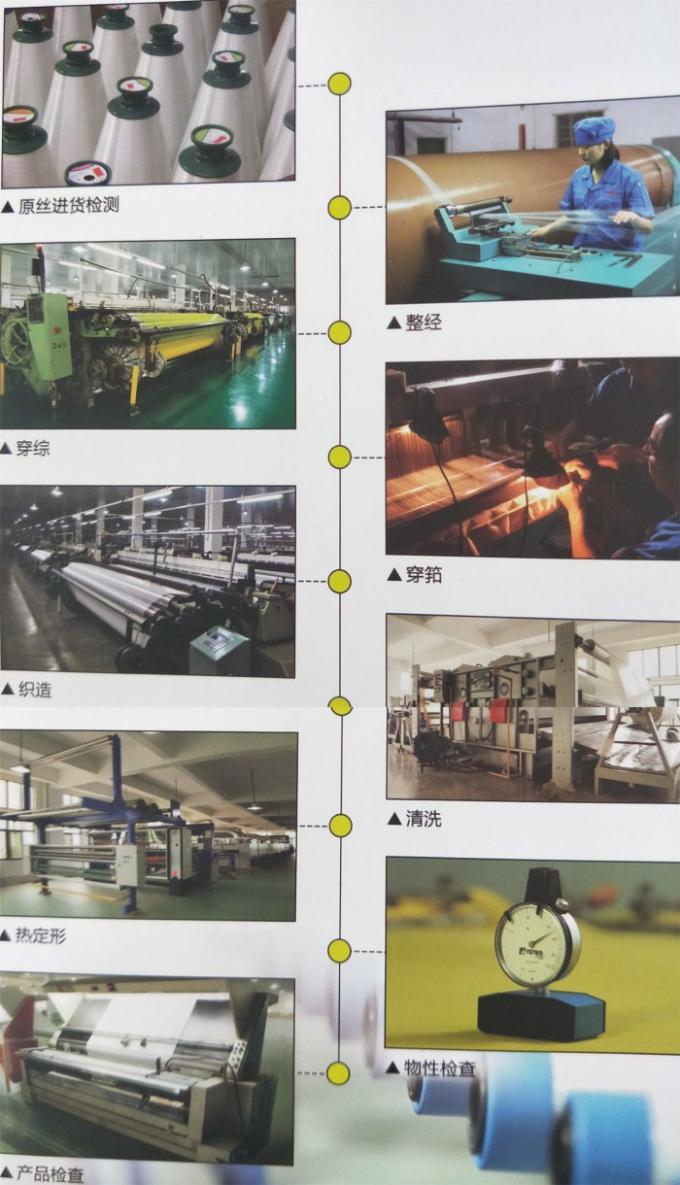

The normal production process of polyester mesh:

1) Material inspection-Imported High Quality Raw Material

Contact Person: Colin Gong

Tel: +8615931178799